The Ultimate Beginner’s Guide to Understanding a Metal Foundry

Wiki Article

Everything About Metal Casting: How Foundries Supply High Quality and Precision in Manufacturing

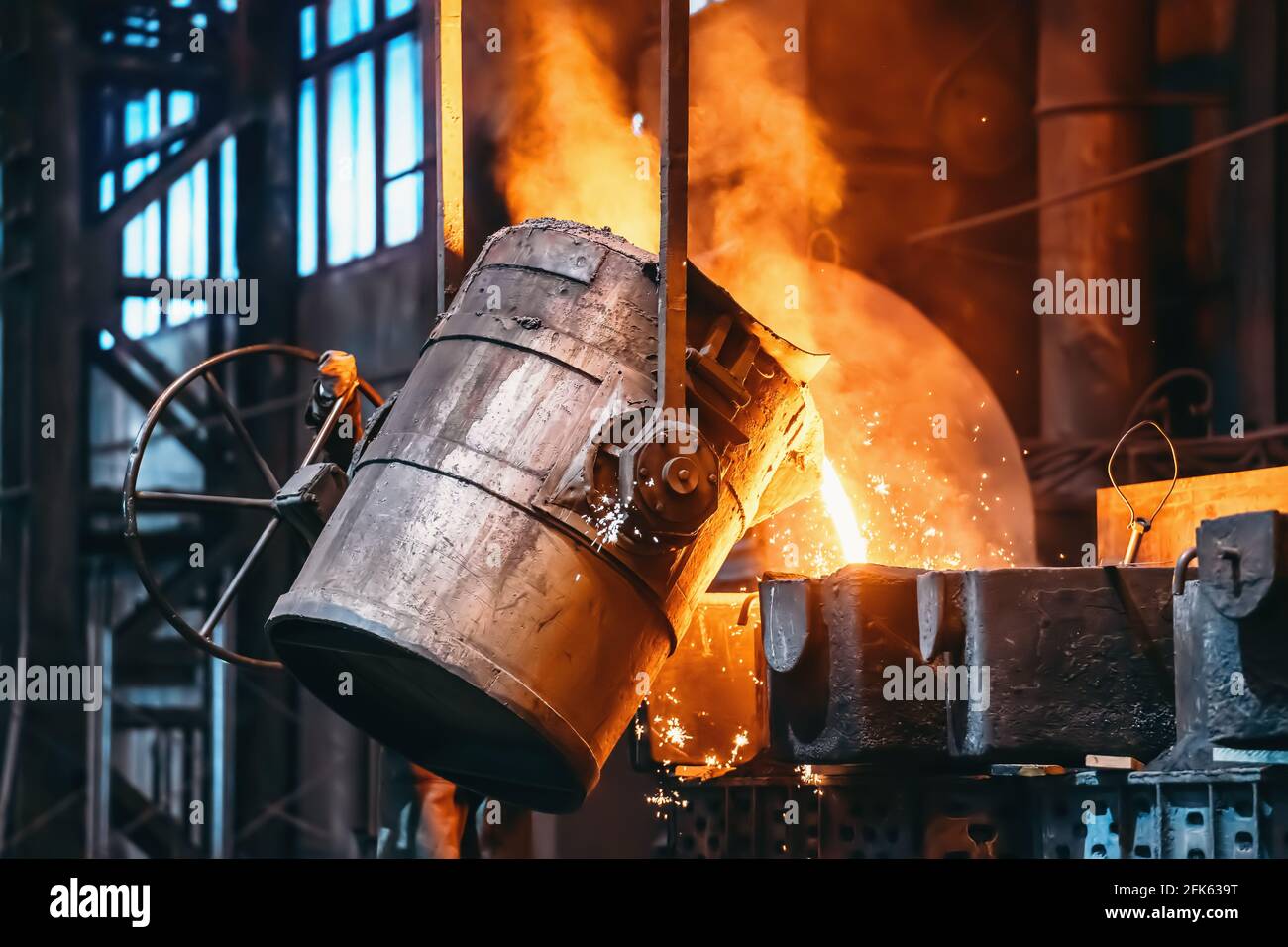

Metal casting stands as a fundamental process in production, where raw metals are changed into details elements. Foundries use different casting approaches to accomplish desired forms and qualities. Each strategy includes its very own set of benefits and limitations. Recognizing these nuances is vital for valuing how top quality and precision are maintained throughout the procedure. The discussion in advance will certainly explore the complex characteristics of metal casting and its significance across several markets.The Essentials of Metal Casting

Metal casting is a fundamental procedure in manufacturing that involves forming molten metal right into preferred kinds. This necessary strategy begins with the choice of raw products, frequently different metal alloys, which are thawed in a heating system. When the metal gets to the suitable temperature, it comes to be liquid and prepared for casting.The process needs a mold and mildew, typically made from sand, metal, or ceramic, which defines the last form of the cast item. When the liquified metal is put right into the mold, it cools down and strengthens, tackling the mold and mildew's contours.

After cooling, the casting is eliminated from the mold, and any needed completing procedures, such as brightening or trimming, are conducted. This method enables suppliers to generate complex forms and parts with high precision and marginal waste. Metal casting is widely utilized across various sectors, from auto to aerospace, emphasizing its significance in modern production.

Kinds of Casting Approaches

While different casting techniques exist, each method is and offers unique benefits matched for various applications. Sand casting, among the most usual approaches, uses sand as the mold and mildew product, enabling complex styles and large components. Investment casting, recognized for its precision, uses a wax pattern coated in ceramic, making it ideal for intricate geometries. Pass away casting, which includes requiring liquified metal into mold and mildews under high stress, is frequently made use of for mass manufacturing of little, in-depth components. In addition, shell molding combines sand and material to create thinner, more exact molds, boosting surface coating. An additional technique, constant casting, enables the manufacturing of long sizes of metal forms, streamlining manufacturing procedures. Each of these techniques plays a pivotal function in the metal casting industry, dealing with details requirements from manufacturing volume to make complexity, consequently contributing to the diversity of applications throughout numerous industries.The Role of Foundries in Production

Foundries offer a crucial function in the manufacturing landscape, as they change raw metals right into usable elements via various casting processes. These centers employ a variety of strategies to create products that satisfy precise specifications, thereby making certain high quality and performance in manufacturing (Metal Casting). By utilizing methods such as sand casting, investment casting, and pass away casting, shops deal with diverse markets, consisting of auto, aerospace, and building

Inevitably, factories are essential to the manufacturing ecosystem, giving vital components that sustain a wide variety of applications and industries. Their precision and versatility drive performance in modern production.

Products Made Use Of in Metal Casting

The selection of products used in metal casting is crucial for accomplishing the wanted buildings and efficiency of the last product. Different steels such as aluminum, iron, and bronze are frequently employed, each offering distinctive advantages. Aluminum is preferred for its corrosion-resistant and light-weight qualities, making it suitable for vehicle and aerospace applications. Iron, especially cast iron, is recognized for its superb fluidity and strength, ideal for hefty equipment and infrastructure components. Bronze, with its premium wear resistance, is commonly utilized in aquatic settings.Additionally, products such as silica sand are often made use of for mold making, providing a great equilibrium between sturdiness and ease of shaping. The choice of products likewise includes additives like fluxes, which enhance the casting procedure by boosting fluidness and minimizing oxidation. Ultimately, the proper selection of these materials considerably influences the effectiveness and top quality of the casting process.

Quality assurance in the Casting Process

Quality control in the casting procedure is necessary to guarantee that final items meet industry criteria and specs. Various evaluation techniques are employed to identify defects and examine the stability of cast elements. Additionally, adherence to developed standards and qualifications boosts the dependability and performance of actors products.Assessment Techniques Employed

Preserving the honesty of cast metal components counts greatly on different inspection techniques. Foundries employ aesthetic inspections as an initial step to recognize surface flaws, such as additions or fractures. Non-destructive screening (NDT) approaches, consisting of ultrasonic screening and radiographic assessment, are crucial for spotting internal imperfections without endangering the element's honesty. Dimensional evaluations using calipers and coordinate measuring devices validate that components fulfill specified tolerances. Additionally, chemical evaluation validates that the alloy composition lines up with wikipedia reference called for requirements. These inspection techniques collectively confirm that the castings satisfy the essential top quality and efficiency standards, inevitably minimizing the danger of failing in their designated applications. Implementing these rigorous inspections is essential for keeping high criteria in metal casting manufacturing.Criteria and Certifications

Specifications and qualifications play an important role in the quality assurance of the casting procedure. Foundries abide by numerous international and industry-specific standards, such as ISO 9001 and ASTM standards, assuring consistency and integrity in their products. These requirements describe the essential requirements for products, production methods, and testing procedures, contributing to a much more reliable news manufacturing process. Qualifications, such as AS9100 for aerospace applications, further emphasize the value of quality control in specialized fields. By getting these qualifications, shops show their commitment to quality, reducing flaws and improving customer contentment. Normal audits and examinations validate conformity, promoting continuous renovation and technology within the market. Eventually, adherence to established criteria grows trust fund in between makers and clients.Advancements in Casting Modern Technology

3D Printing Integration

Incorporating 3D printing modern technology into metal casting procedures is reinventing the manufacturing landscape. This ingenious fusion enhances the style and manufacturing of complicated geometries that typical methods struggle to achieve. By utilizing additive manufacturing for developing cores and mold and mildews, foundries can substantially minimize preparations and product waste. 3D printing permits for quick prototyping, making it possible for makers to check styles swiftly and successfully, thereby facilitating iterative renovations. This modern technology additionally sustains the production of lightweight components, which are necessary in markets like aerospace and automotive. As an outcome, the assimilation of 3D printing not just enhances operations but additionally boosts the precision and high quality of cast metal items, noting a notable development in the sector.Automated Manufacturing Processes

The developments in 3D printing have led the way for further developments in automated manufacturing processes within metal casting. Foundries are increasingly embracing robotics and automation to improve efficiency and precision. Automated systems simplify the entire casting workflow, from mold and mildew development to pouring and ending up. Smart sensing units and real-time monitoring permit for accurate control of temperature levels and material circulation, minimizing waste and improving top quality. Additionally, software options help with far better style and simulation, making it possible for suppliers to enhance processes prior to production begins. These automated production processes not just reduce labor prices but additionally decrease human error, ensuring constant result. Therefore, the combination of sophisticated modern technologies in metal casting is reinventing production capacities and meeting the expanding needs of different sectors.Advanced Product Development

As markets require greater efficiency and sustainability, innovations in material development for metal casting are emerging as a vital emphasis. Designers and scientists are discovering brand-new alloys and compounds that boost mechanical residential properties while reducing environmental impact. Developments include lightweight materials that keep strength, enabling better fuel performance in transport applications. In addition, the unification of recycled products is ending up being a lot more common, lining up with sustainability goals. Advanced casting techniques, such as 3D printing and precision molding, enable the production of see here now complicated geometries that conventional methods can not achieve. These growths not just enhance the functionality of cast components but additionally improve production efficiency. On the whole, the continual development of material scientific research drives the future of metal casting, fulfilling the needs of modern sectors.

Applications of Metal Casting Throughout Industries

Metal casting plays a crucial function in numerous industries, as it permits the production of complex forms and top quality components with loved one performance - Aluminum Foundry. In the auto market, cast steels are crucial for creating engine blocks, transmission situations, and other vital parts that call for sturdiness and precision. Aerospace markets make use of metal casting for components like turbine blades and architectural elements, where dependability is vitalAdditionally, equipment and equipment production gain from metal casting by creating equipments, real estates, and other complex components that enhance performance. The construction market additionally uses metal casting for building features, architectural supports, and installations, showcasing flexibility.

The medical area counts on actors steels for medical instruments and implants, emphasizing the requirement for biocompatibility. On the whole, metal casting is a foundational process across several markets, giving solutions that meet rigorous top quality standards and efficiency needs.

Regularly Asked Questions

What Precaution Are Absorbed Metal Casting Foundries?

In metal casting factories, precaution consist of protective gear, ventilation systems, regular equipment maintenance, employee training, and emergency protocols to reduce risks related to heats, dangerous materials, and potential accidents during the casting procedure.Just How Do Foundries Take Care Of Waste and Environmental Influence?

Foundries handle waste and environmental impact through reusing products, applying purification systems for discharges, and adhering to laws - Aluminum Casting. They also embrace sustainable practices, such as minimizing power usage and utilizing environmentally friendly substances in their proceduresWhat Are the Expenses Connected With Metal Casting Procedures?

The expenses connected with metal casting processes consist of raw products, labor, equipment upkeep, power usage, and waste management. In addition, variations in market costs and compliance with ecological guidelines can greatly impact general costs for shops.Exactly How Does Metal Casting Compare to Other Production Techniques?

Metal casting uses unique advantages, such as intricate shapes and high product effectiveness, contrasted to techniques like machining or stamping. However, it may involve longer preparations and higher first expenses, depending on task specifications.

What Profession Opportunities Exist in the Metal Casting Sector?

The metal casting industry uses various profession possibilities, including shop administration, procedure design, high quality guarantee, mold and mildew style, and equipment operation. Experts can additionally pursue functions in study and development, sales, and ecological health and wellness.Metal casting stands as a fundamental procedure in manufacturing, where raw metals are transformed right into specific elements. Metal casting is an essential procedure in manufacturing that involves shaping liquified metal right into preferred forms. Another approach, continuous casting, enables the production of long lengths of metal shapes, streamlining manufacturing procedures. The prices linked with metal casting procedures include raw materials, labor, tools upkeep, power intake, and waste monitoring. The metal casting industry offers various profession chances, consisting of factory administration, procedure engineering, high quality guarantee, mold and mildew style, and device operation.

Report this wiki page